Riders hear a lot about suspension in discussions about motorcycle performance. We all know what shocks and forks are, but motorcycle suspension has a language of it’s own, so we asked our staff and some of the experts in the field we work with to put together this directory of motorcycle suspension terms. Hopefully, it’ll help you when you’re ready to upgrade your ride!

Bottoming: When your bike hits a large bump or lands from a jump the suspension can “bottom out” as the wheels move up toward the bike quickly and the suspension hits the end of its travel. “Bottoming out” usually happens very quickly like slamming a door closed and can easily upset the balance and damage the motorcycle.

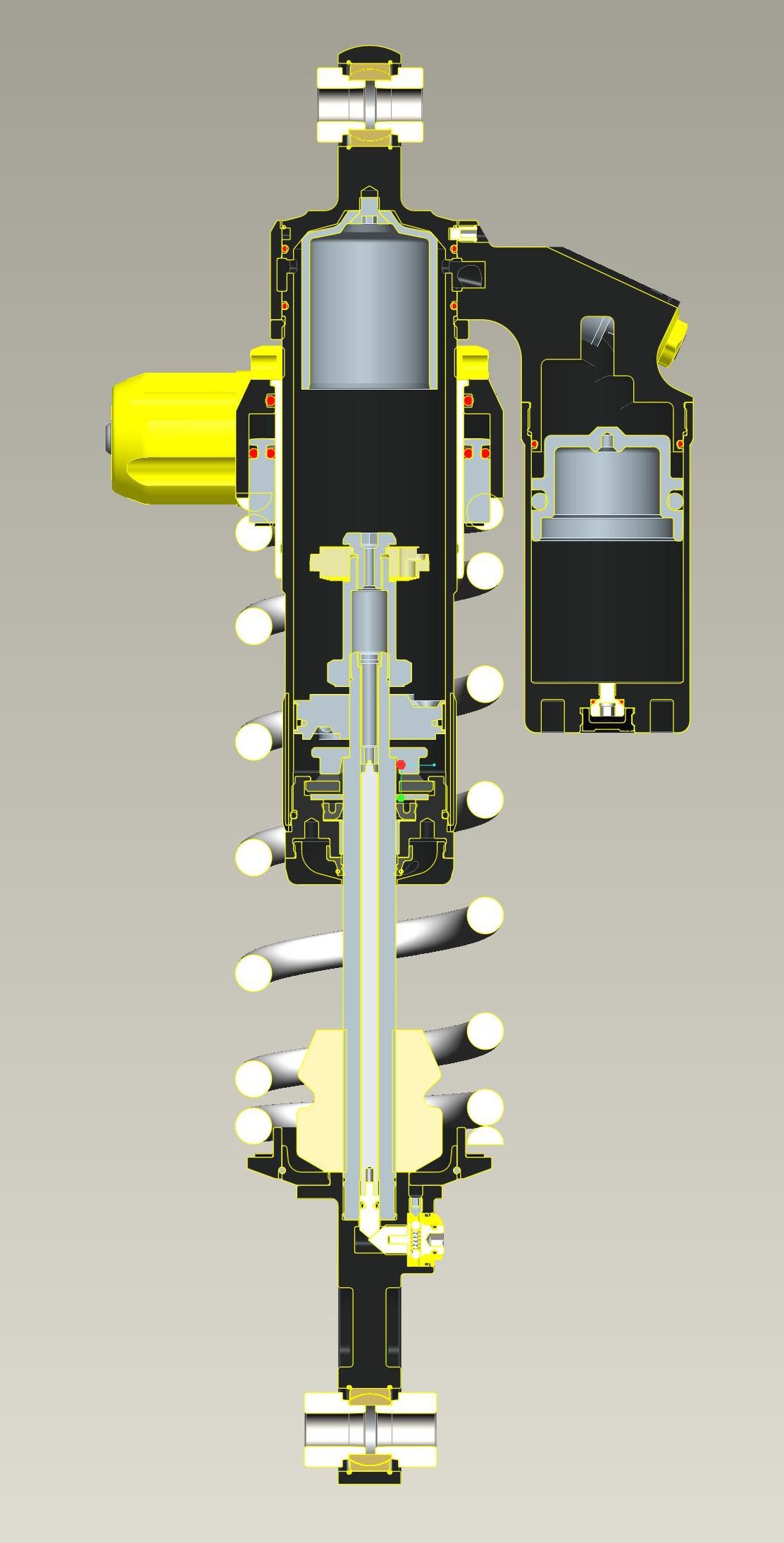

Closed Cartridge: Modern motorcycle forks come in many different designs but many of them contain a ‘cartridge’ inside the fork that uses oil flow during compression and extension to control the wheel movement. The two main types of ‘cartridges’ are ‘open’ and ‘closed’ and these names describe how the cartridge interacts with the fork that it is contained within. An ‘open cartridge’ uses the same oil that lubricates the fork’s up and down action to create a damping effect on the motion of the wheel. A ‘closed cartridge’ is a sealed unit that keeps its oil separate from the lubrication oil in the fork.

The sealed nature of a ‘closed cartridge’ allows the manufacturer to fine tune the damping action and create a more high performance fork system. Manufacturers can use special oils that won’t be contaminated by the working elements of the fork and they can pressurize the damping oil so that it won’t foam under heavy use. When the oil is foamless, damping action is much more consistent under heavy use and high heat.

Compression (high and low speed): The term ‘compression’ refers to the compressing of the shock absorber. ‘High’ and ‘low’ refer to the speed that the shock is compressing, which is also called “shaft speed.”

High shaft speed is experienced when the bike is landing from a jump or hitting a large square faced bump like a big pot-hole. Low shaft speed is experienced when riding over rolling humps in a road or transitioning between right and left turns quickly.

Shocks that allow adjustment of high speed and low compression damping give the riders the ability to optimize performance to meet their own preferences.

Damping: Resistance that suspension puts against a quickly moving wheel is called “damping force.” Without any damping, the wheel would bounce uncontrolled with only the spring and the ground pushing against the wheel. ‘Damping’ is often mistakenly referred to as ‘dampening’ but don’t confuse the two because one is used for suspension and the other is used for gardening. Having effective damping is one of the most important elements of comfort and bike control.

Dynamic Damping Adjustment/Action (DDA): Until fairly recently, suspension was something that could only be adjusted with tools while the motorcycle was stopped. Electronic suspension adjustment (ESA in BMW speak) allows riders to choose different damping settings and ride height, while riding their bikes by simply pressing a button. This system changes the suspension adjusters in the same way that a rider would if they were “turning the clickers” with the bike parked.

The passive ESA system makes the adjustments that the rider asks for and leaves the shock alone once the adjustment has been made. This allows the rider to choose settings to match the riding situation for terrain, passenger, luggage-load and rider preference.

Dynamic ESA goes one step further than passive ESA and uses information from wheel travel sensors, wheel speed sensors, gyroscopic sensors, throttle position, brake switches, and the ride mode selected to constantly and rapidly make changes to the suspension damping. This system’s goal is to monitor the terrain and constantly adjust the suspension to respond perfectly to varying conditions on the fly.

Emulsion Shock: Every shock absorber needs to contain some gas because the shock fluid cannot be compressed as the shock shaft slides into the body and displaces that fluid. An emulsion shock is a very simple design that simply leaves an air gap at the top of the sealed shock chamber. This air mixes with the shock oil causing a foamy mixture. The valving of the shock is set up to work properly with the oil in this foamy condition.

The emulsion shock is much easier and cheaper to build than other designs but it does not perform consistently because of the foamed oil and drastic effect of temperature on gas bubbles in the foam.

ESA: Until fairly recently suspension was something that could only be adjusted with tools while the motorcycle was stopped. Electronic suspension adjustment (ESA in BMW speak) allows riders to choose different ride heights and damping settings by simply pressing a button. This system changes the suspension damping in the same way that a rider would if they were “turning the clickers” when the bike is parked. This allows riders to choose settings that match riding conditions and load. The ESA system makes the adjustments that the rider asks for, and leaves the shock alone once the adjustment has been made.

Fork Springs: A motorcycle fork has coil springs inside of it that are just smaller and longer versions of the coil spring used on the rear shock. The fork spring is very important because it holds the suspension up against the weight of the motorcycle and it’s load. Selecting the correct fork spring is also very important because if the rider is heavier or carries more gear than the springs are designed for, the suspension will sit lower than designed and not respond the correct way when riding. The current spring rate will allow the correct sag to be achieved, which is required for optimum handling.

Pre-Load: When you install a spring on a shock or into forks, you want the spring to be slightly compressed when the shock or fork is fully extended so that it doesn’t become loose and fall out of its position when the suspension moves. The amount that the spring is compressed when the suspension is fully extended is called the “pre-load.” Spring pre-load can be used to adjust the ride height of the bike for changes in rider weights or luggage loads.

Pre-Load Adjuster: There are different ways to adjust the preload of a spring. The most common type for a shock absorber is simply a threaded collar that you use like a big nut to tighten down against the force of the shock spring. The threaded collars are difficult to reach on most motorcycles and aren’t practical to use for making adjustments to pre-load while the shock is still mounted on the motorcycle.

The Touratech Explore HP, Expedition, and Extreme shocks include a hydraulic pre-load adjuster that makes it very easy to add or remove pre-load from the shock spring while the shock is mounted on the motorcycle. The Touratech PA is a knob which is turned by hand that pumps hydraulic oil pushing a floating piston against the shock spring to increase ride height.

Progressive Springs: Progressive springs have the coils wound in such a way that as the spring is compressed, it’s rate of resistance increases progressively. This is different than a “straight rate” spring where the rate of resistance increases at a constant rate. Progressive springs are very common in motorcycle forks where the spring is compressed many inches and the progressive increase of spring pressure makes a big difference.

Rebound: The term ‘rebound’ refers to the extending of the shock absorber that occurs when the wheel moves away from the motorcycle. Rebound damping is the force that the shock exerts against the pressure of the spring, pushing the shock back to its full extension.

Rebound damping will make the shock extend faster or slower and should be tuned carefully. If the rebound damping is too strong, the tire will not return to the ground quickly enough after hitting a bump and the bike will lose traction as the tire is in the air. If the rebound damping isn’t strong enough, the shock will extend so quickly after hitting a bump that the shock will hit its full extension very quickly and the bike will bounce like a pogo stick.

Ride Modes: Some newer motorcycles include electronics packages that can change how the bike responds to rider inputs based on what ride mode is selected. The ride modes have names like “Rain, Road, Dynamic, Enduro, Sport, or Race” and they change many things about the bike. Most bikes will use ride modes to change things like throttle turn feel, power output, traction control, ABS, and suspension settings. Ride modes and electronic controls typically make it much easier and safer to ride bikes with VERY high performance potential.

Sag: Suspension sag is the percentage of overall suspension travel that is used when the bike is sitting on level ground with the weight of the rider and gear loaded. If the suspension is designed to have 30% of its overall travel used as sag then it has 70% available to absorb a bump in the road and 30% available to keep the tire on the ground through a dip in the road.

Sag is a very important adjustment on a motorcycle because it affects chassis geometry and suspension travel. If the bike doesn’t sit level front to rear, the steering angles are not correct and the handling will suffer. If the spring is too soft and 50% of the overall travel is taken up with an incorrect sag adjustment, the bike has less travel available to absorb a bump in the road before the suspension bottoms out. If the spring is too stiff and only 5% of the overall travel is taken up by an incorrect sag adjustment, the tire won’t be able to follow ripples or dips in the road and the bike will lose traction as the tire leaves the ground.

Seals: Clean oil is very important to good suspension action but minimal friction is also very important. The balance between excellent sealing and low friction is compounded in shock absorbers because the oil is under enormous pressure in the shock. Touratech Suspension is equipped with a proprietary low-friction seal that is supported by a Teflon back-up ring. This Teflon backbone keeps the seal from deforming under pressure and reduces friction on the shaft.

Separation Bladder: There are different ways to separate the oil from compressible gas inside a shock or fork. A separation bladder is used in the Touratech sealed fork cartridges to separate the damping oil from the high pressure nitrogen gas. The bladder is basically a thick rubber balloon that submerged in the oil and sealed against the wall of the cartridge before being filled with ~75psi of nitrogen gas. The pressurized nitrogen pocket gives the oil a place to expand when it is displaced by the cartridge shaft and it also keeps the oil under pressure so that it won’t cavitate when the fork is working hard in rough terrain.

Stepper Motor: The electric motor used in Touratech Plug-and-Travel suspension is called a stepper motor. A stepper motor can be finely controlled to quickly turn a controlled number of times. These motors are very accurate and are used to make rapid, fine adjustments to suspension settings.

If you have questions about suspension or anything else having to do with motorcycle travel call a Touratech Adventure Expert at 1-800-491-2926 and check out our full line of amazing suspension products built for adventure!